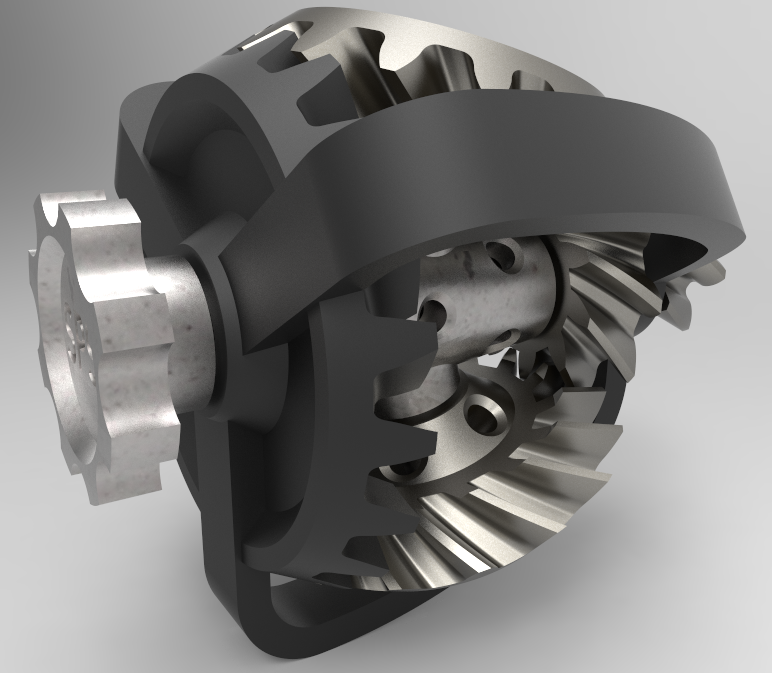

I designed this little epicyclic gear reducer as a project for a Rapid Design and Manufacture (MET3332) class I am taking this summer. We were asked to design an interesting mechanical device that did not require assembly, and took advantage of the unique capabilities of additively manufactured parts. We were also challenged to keep the material volume below 1in3.

Inspiration came from drawings of old mill equipment, which used this type of arrangement to provide a faster rotating shaft within a slower hollow shaft. It seems like a planetary gear box would be more practical, but it may be that at the time bevel gears were easier to make.

The spiral bevel gears were generated using GearTrax for Solidworks. All clearances are .020in which should be enough to allow the printer to generate adequate support material to keep the parts from fusing together. The spiral gears result in a very smooth and quiet operation.

CAD models are available on GrabCAD.